Saw blades are an essential tool in the hardware industry, and the quality of the blade can significantly impact the efficiency and precision of cutting. Tungsten carbide saw blades have become increasingly popular due to their ability to withstand high temperatures and retain their sharpness for longer periods. In order to create a high-quality tungsten carbide saw blade, the welding process is crucial. Danyang Qiliang Machinery Co., Ltd. is a leading enterprise in the hardware tool industry, specializing in the production and development of automation equipment, including tungsten carbide saw blades. With their extensive experience and continuous market penetration, their products have received unanimous recognition for their high quality and perfect after-sales service.

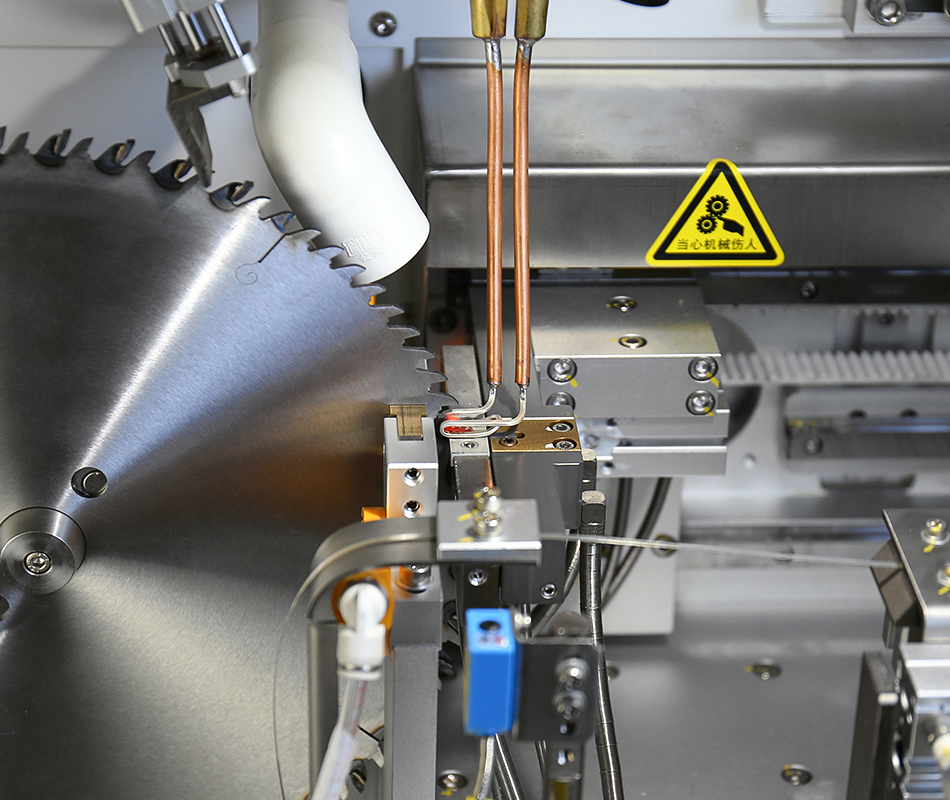

One of the key processes in manufacturing a tungsten carbide saw blade is the welding of the carbide tips onto the blade. Saw blade brazing is a conventional process where the matrix and alloy are bonded together through heating. The brazing temperature and heating rate play a crucial role in determining the welding quality. If the temperature is too high or the heating rate is too fast, it can result in internal stress within the cemented carbide, leading to cracks and chipping after welding.

When brazing welding, it is essential to ensure that the surface of the substrate and alloy is free of dust and oil. Any oil stains can be cleaned with alcohol or gasoline, while dust on the substrate can be blown away with an air gun. This meticulous preparation is necessary to ensure a strong and durable bond between the tungsten carbide and the saw blade.

The overall process of saw blade brazing typically involves heating, insulation, cooling, tempering, and completion. Each of these steps requires precision and expertise to achieve the desired quality in the tungsten carbide saw blade. With 25 national technology patents, Danyang Qiliang Machinery Co., Ltd. has demonstrated their commitment to innovation and excellence in the hardware tool industry.

The welding of tungsten carbide saw blades is a complex and delicate process that requires advanced equipment and expertise. Danyang Qiliang Machinery Co., Ltd. has established itself as a reliable and innovative provider of automation equipment for the hardware tool industry. Their products have been widely recognized for their high quality, short delivery time, and impeccable after-sales service, serving over 800 customers both domestically and internationally.

In conclusion, the welding of tungsten carbide saw blades is a critical step in their production process. With the right techniques and equipment, a strong and durable bond can be achieved, resulting in high-quality saw blades that meet the demands of the hardware industry. Danyang Qiliang Machinery Co., Ltd. has made significant strides in this field, positioning itself as a reputable and innovative enterprise in the hardware tool industry.